Nanochips a prueba de agua

A single drop of water can be fatal to electrical circuits. To prevent water damage, current electronic devices are well sealed and packaged with polymer passivation. Researchers in Korea have now gone one step further and made water resistance a feature of the device itself by incorporating nonwetting, superhydrophobic components into the electronic device. They demonstrated this novel idea with a source/drain structure in a thin-film transistor.

«Our work combines superhydorphobicity with electronic devices, especially resistive switching memory devices» Kijung Yong, a professor in the Surface Chemistry Laboratory of Electronic Materials at Pohang University of Science and Technology (POSTECH), tells Nanowerk. «Although much research has been done on either topic, few works report the combination of combining superhydrophobicity and electronic devices. We believe this is a novel approach to combine two different concepts to get a synergic effects.»

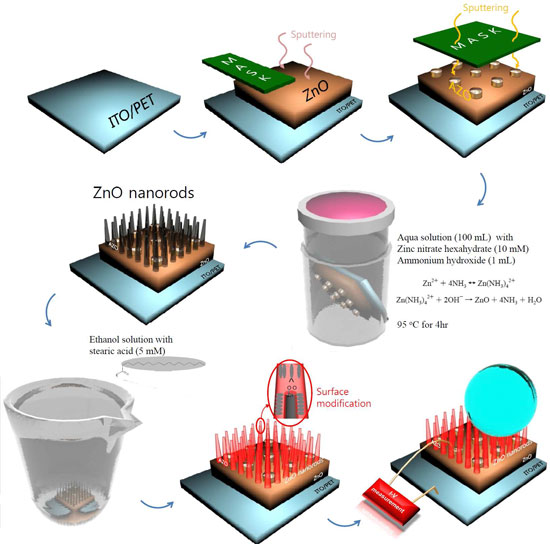

Reporting their work in the October 11, 2011 edition of Advanced Materials («Overcoming The Water Vulnerability Of Electronic Devices: A Highly Water-Resistant ZnO Nanodevice With Multifunctionality»), the team demonstrates a ZnO NRs/AZO/ZnO/ITO/PET resistive switching device that is waterproof, transparent, and flexible.

This report presents a useful and simple fabrication route that is widely applicable to various general electronic devices, especially highly water-vulnerable organic devices or non-protected metal interconnections in electronic devices.

Yong’s group has worked on superhydrophobic surface fabrication using nanowires for several years (see for instance: «Wettability Control and Water Droplet Dynamics on SiC-SiO2 Core-Shell Nanowires» or «Impact dynamics of water droplets on chemically modified WOx nanowire arrays»).

The group has also worked on new memory devices such as resistive memory. One day, Yong thought it might be quite useful to combine the team’s expertise in these two areas. The result has been this highly water-resistant resistive switching device.

Device fabrication procedure for ZnO NRs/AZO/ZnO/ITO/PET structure. (Reprinted with permission from Wiley-VCH Verlag)

Device fabrication procedure for ZnO NRs/AZO/ZnO/ITO/PET structure. (Reprinted with permission from Wiley-VCH Verlag)

The researchers employed surface treatment with a self-assembled monolayer to make the surface of their ZnO nanorod array superhydrophobic. For that purpose, they grew well-aligned, high-density, columnar ZnO nanorods on the surface of the device. The dimensions of the nanorods were about 260 nm long and 50 nm in diameter.

«With longer nanorods, the effect of superhydrophobicity can be enhanced because of an increase in surface roughness,» explains Yong. «To achieve high transmittance, however, an optimum length of nanorods was necessary. Thus, we grew ZnO nanorods less than 300 nm in length by controlling the amount of ammonium hydroxide and the reaction time for the nanorod growth.»

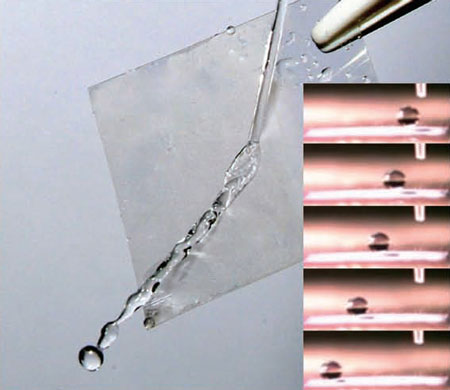

When they evaluated the superhydrophobicity in their device, the team measured the contact angle of a deionized water droplet of over 150°, which is remarkably high compared with the contact angle of 30° for the unmodified device. As they expected, when they poured excessive amounts of water on the superhydrophobic device, the water bounced off the surface upon contact, and the remaining water droplets rolled off the surface.

«We found that the switching performance, such as the resistance ratio and process voltage, was not affected by the application of water even up to a significant number of cycles,» says Yong.

Water-resistant characteristics of the fabricated device. (Reprinted with permission from Wiley-VCH Verlag)

Because water-resistant passivation is even more important to emerging devices such as e-readers, tablets, or e-textiles, the team also investigated the flexibility and transparency of the fabricated resistive switching device while maintaining the water-resistance.

Water-resistant characteristics of the fabricated device. (Reprinted with permission from Wiley-VCH Verlag)

Yong notes that the tolerance level of flexibility can be further enhanced with optimization of the device structure, considering parameters such as film thickness, a flexible substrate material, and enhancements in the adhesion between layers. Another issue they are working on is to study the dependance of their device’s stability on hydrostatic pressure.

Etiquetas: nanochips, nanomaterials, waterproof, wettability